How are Vanilla Beans Harvested?

How are Vanilla Beans Harvested?

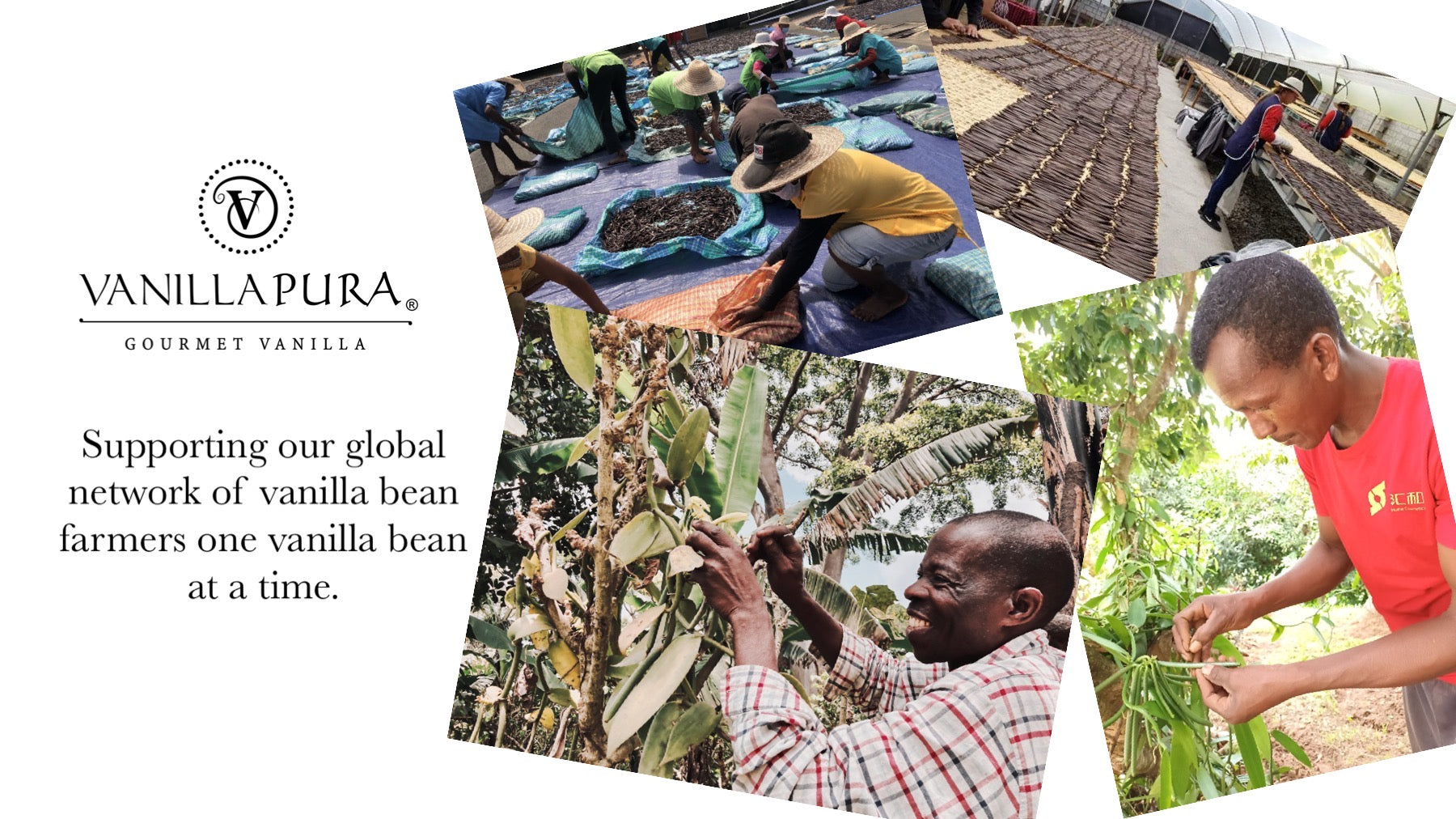

Cultivating a quality vanilla bean is an arduous process. It is so labor intensive, that the vanilla bean is the second most expensive spice in the world, just behind saffron. Furthermore, poor weather conditions often lead to global vanilla bean shortages that can boost the cost of vanilla beans even higher than saffron.

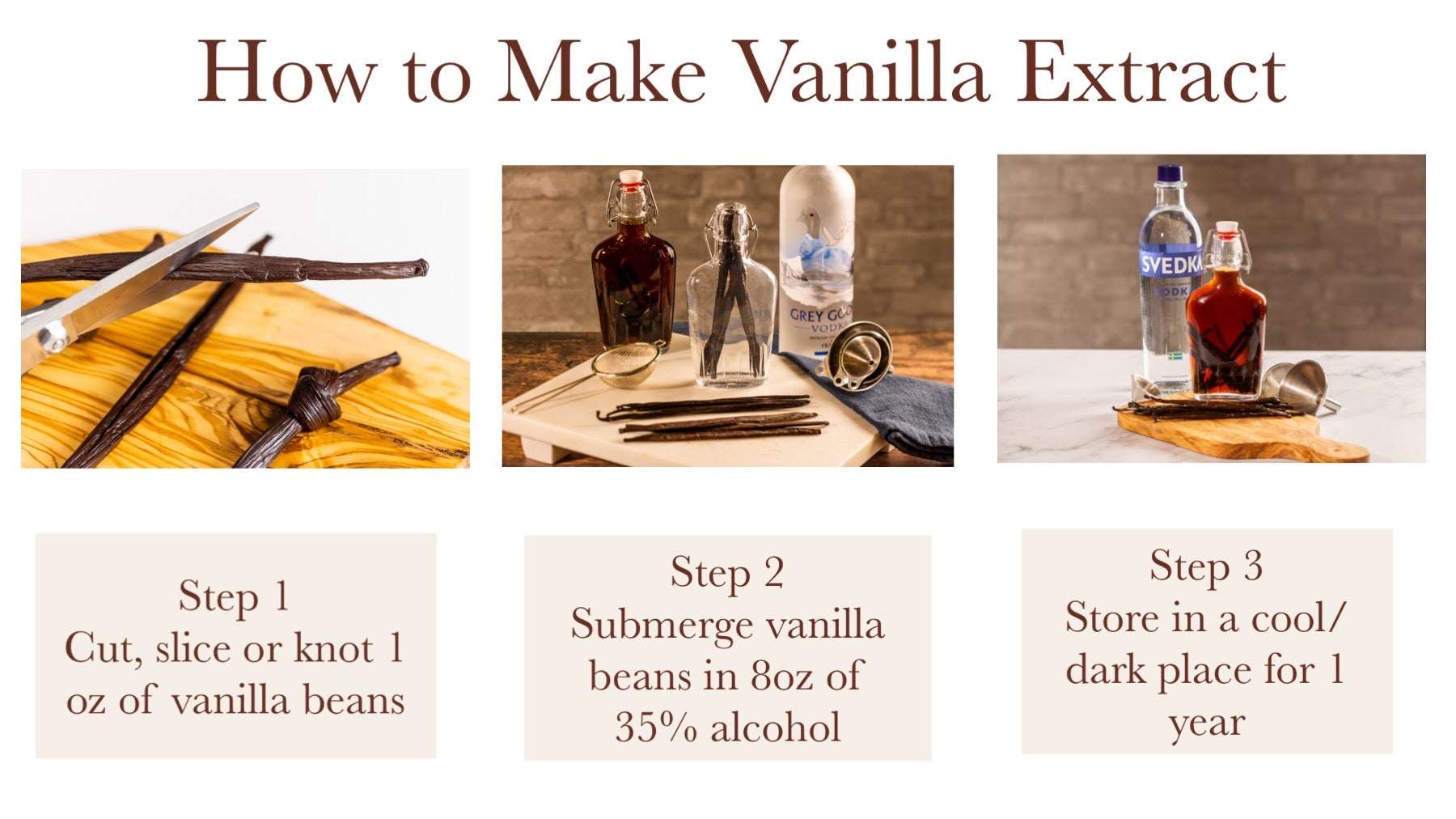

Order The Art of Extract Making. The first professionally published extract-making book of its kind will begin shipping in October, 2023.

Vanilla beans are grown in tropical regions around the world, where year-round warm temperatures and sufficient rainfall create soil conditions and climate that are suitable for proper growth. They are actually green (not brown) when they are harvested.

(Vanilla Orchid - Reunion, Madagascar)

Vanilla Beans grow within the "Bean Belt" - a warm climate zone that is 25 degrees north and south of the equator. Coffee beans, cocoa beans and various other beans all grow within this region. Vanilla Beans, however, are the most sensitive since they are derived from a delicate flower.

Like many orchids, the Vanilla Planifolia (the vanilla bean orchid) is an epiphyte that lives on a host tree. It’s a vine that grows rapidly up and around an existing tree, but does not draw on the tree’s nutrients. The vanilla orchid can be up to 3 years old before it begins to grow the delicate orchid that ultimately becomes a vanilla bean. The pods themselves require an additional 9-10 months of growth before they can be harvested.

(4 year-old vanilla bean vines growing on Caribbean Mahogany trees in Yucatan, Mexico. Picture taken by Paul and Jill of VanillaPura during their December 2021 visit to inspect bean drying post harvest. )

Every single vanilla bean orchid must be pollinated by hand in order for a vanilla bean to grow. This is a result of the likely extinction of the vanilla bean bee. Typically, pollination must occur within 6 hours of the orchid blooming to result in successful pollination and to yield a single vanilla bean 9 months later.

Here is a 43-second video that we captured in Hawaii as we visited one of our farmers. This shows exactly how each orchid is pollinated.

The morning of our visit to the Hawaii vanilla farm, more than 1,000 orchids were successfully pollinated.

Of course, pollination is far from the last step. The pollinated orchid must now remain in the right climate, shade, humidity, etc. to grow a healthy bean.

Healthy vanilla beans are green and typically 4-9 inches long (depending on the species) before they are ready to be harvested. Here is an image of healthy vanilla beans taken at one of our Caribbean farms: (yes, that's a banana tree in the background!)

Once mature, healthy beans are clipped from the vines and harvesting begins. There are multiple steps to successful harvesting that we will outline here.

Stages of Vanilla Harvesting

There are 6 stages of vanilla harvesting. For this process to be successful, it requires a delicate balance between moisture and average temperature.

Here are the 6 stages:

1. Harvesting

- Beans are carefully cut from the stem using a sharp knife. At this phase they are green and odorless.

- The outer vegetative skin of the bean is killed by soaking it in hot water to keep it from growing further. This not only kills the skin of the vanilla bean, but also kills other potential pathogens.

- The vanilla pods are exposed to the hot conditions during the day and then wrapped in blankets at night to "sweat" out their inherent flavor and aroma. It is in this phase that the wonderful, familiar flavor and aroma of vanilla begins to present itself.

- Similar to sweating, this phase is more art than science, but science is still an important factor. The vanilla beans are laid out into the hot sun all day, and then brought inside at night, until the moisture content in the beans is down to 18%-35%. (Grade-b vanilla is dried longer with a moisture content around 20%. Grade-a is dried for a shorter period of time with a moisture content around 30%.)

(Vanilla beans drying in Yucatan, Mexico)

5. Grading- Once dried, vanilla beans are laid out and graded based on their quality, shape and moisture content into various categories such as "grade-A", "grade-B", "gourmet", "black", etc. Grade-a and Grade-b are based on moisture content and easier to quantify. While "gourmet" or "black" are much more subjective.

- The dried beans are separated by grading glass, bundled and packaged usually vacuum sealed. Vacuum sealing is important because it ensures the bean's moisture remains the same. Moisture can't get in and moisture can't get out. This ensures that the grade of the bean stays consistent from the farm to the consumer.

The entire process from planting the vanilla bean through final packaging can require up to four years, making this little vanilla bean one of the most complicated fruits on our planet.

When vanilla beans are received at VanillaPura, each is bean is individually inspected to ensure that quality standards are met. After a thorough inspection, we vacuum seal the vanilla beans in pouches based on weight or bean quantity, and we ship them in sealed, bubble-lined envelopes or boxes.

When vanilla beans are received by our customers, we recommend that the beans remain in their vacuum-sealed pouch, in a cool, dry and dark place until they are ready to be used. Shelf life can be as long as one year, but we recommend using them immediately. The safest place they can be kept is submerged in alcohol where it is impossible for mold to grow.

Visit our comprehensive extract-making guide center for more essential extract making tips and ongoing education.

(Paul & Jill of VanillaPura inspecting the pollination of vanilla orchids with one of their Hawaiian farmers.)